In the modern mechanical industry, bolt connection is widely used, especially in the pressure vessel industry, which has the advantages of reliable connection, easy disassembly and maintenance. The initial pre tightening force on the bolt not only ensures the sealing performance of the connection [1], but also prevents the connected parts from relative movement under external load [2]. Common bolt failure forms include fatigue, bolt cutting and loosening [3]. Bolt failure will not only increase the maintenance cost and unnecessary downtime of industrial machinery, but also cause some serious industrial accidents [4]

Good bolt connection performance not only depends on the initial preload [5g7], friction coefficient of contact surface [8g9], material [10], etc., but also depends on the bolt diameter [11] and the assembly position between bolt and bolt hole. Many scholars have done a lot of research on bolt assembly. Lawlor and McCarthy et al. [12g13] studied the effect of bolt hole clearance on bolt connection. The research shows that the assembly clearance of bolt and bolt hole not only affects the load distribution, but also affects the fatigue life of bolt.

Ma Chuanbao et al. [14] studied the deviation of the axis from the hole center, considered the probability of the bolt and bolt hole assembly success, and also considered the influence of the position degree on the double hole bolt connection. McCarthy and Egan et al. [15g16] studied the influence of assembly clearance on bolted connection. The research shows that assembly clearance can affect the strength, rigidity and fatigue life of bolted connection, but the influence of location is not considered in the research. At present, the research on the influence of bolt assembly position on the connection performance is not perfect, and there is no theoretical or experimental quantitative research on the influence of assembly position on the connection performance. This paper studies the influence of bolt assembly position on bolt connection performance, and determines the influence of bolt and bolt hole relative position on bolt reliability and connection life.

1. Real test

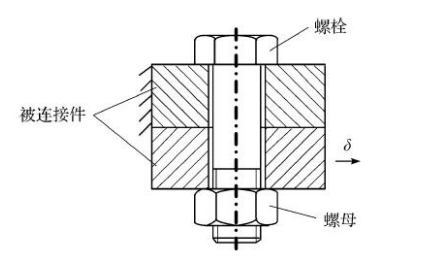

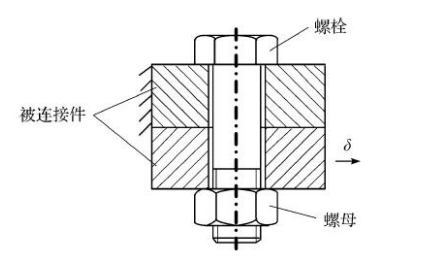

The bolt connection can be simplified as Figure 1, assuming that the external load is transverse shear load, which is applied to any connection.

In order to study the influence of assembly position between bolt and bolt hole on bolt connection, the experimental device is designed, as shown in Figure 3. In the experiment, M12 bolts and nuts are used, with a pitch of 1.75mm and a material of 304 stainless steel; the connection material is 304 stainless steel, with a thickness of 18mm, the diameter of bolt hole is 12.7mm, and the maximum gap between bolt and bolt hole is 0.7mm. In order to protect the contact surface of the connection, copper tape and gasket are placed between the connection and between the nut and the connection. Among them, the copper strip is coated with lubricating oil. The gasket material is 304 stainless steel. Before the experiment, each contact surface should be scrubbed with anhydrous alcohol to remove the oil and impurities on the surface. In the experiment, the change of bolt clamping force is collected by load sensor, and its maximum range is 50kN. The experimental device is placed in Instron 8872, and its maximum tensile load is 25kn, which can meet the experimental requirements. The experiment is carried out at room temperature. One end of the connector is fixed and one end is applied with cyclic dynamic load.